Futureproof manufacturing with automation is no longer optional – it’s essential.

As we know, current manufacturing cannot be, and is most certainly not, business as usual.

With ongoing market disruptions, supply chain challenges, and let’s not forget, the current recruitment crisis and difficulty in finding skilled workers, manufacturing is facing it all.

Yet, as businesses, we’re continuously being asked to do more – and we mean a lot more – with a lot less.

There are greater demands on improving and increasing productivity levels while maintaining quality. Manufacturers now must consider how to futureproof their operations, and understand how technology plays a critical role in making this happen.

Why You Must Futureproof Manufacturing with Automation

Futureproofing your business, manufacturing processes, and systems involves anticipating and preparing for potential challenges and putting in place robust plans to minimise their impact on business operations.

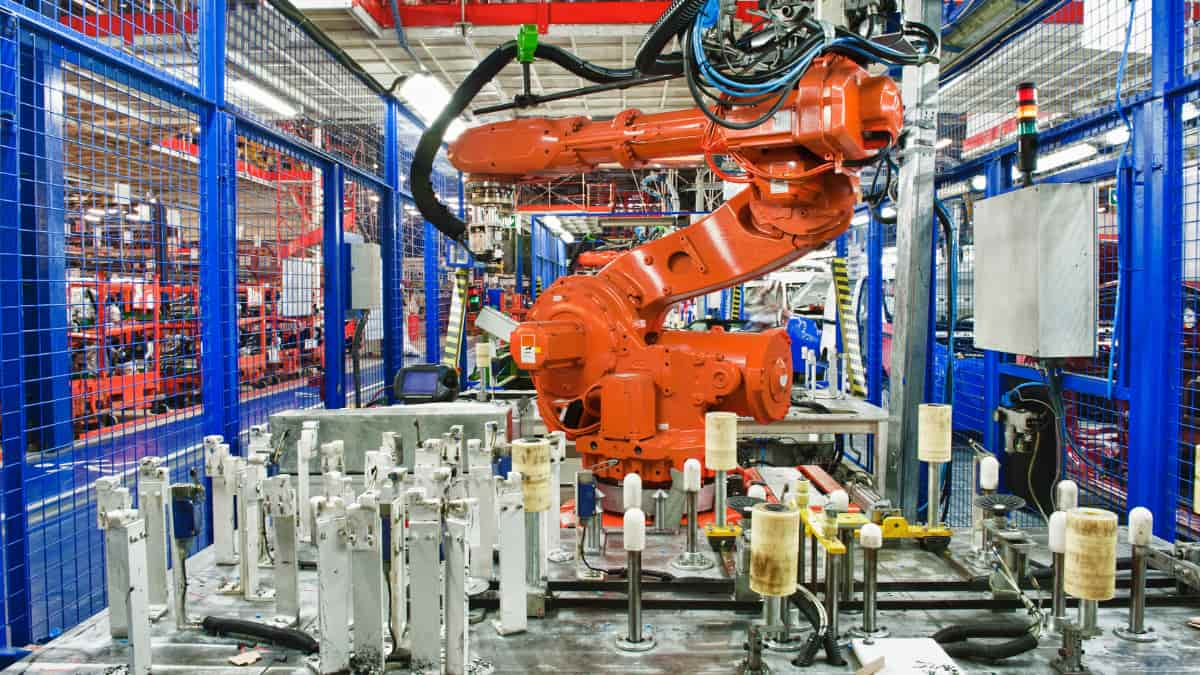

Automation is now seen as a vital ingredient in supporting the sustainability of R&D as well as manufacturing processes. It not only supports current production levels and quality but also helps to improve growth and revenue and ensure continued long-term success.

How Automation Futureproofs Your Production Process

Because with the rightly identified automation, manufacturers can:

Track industry changes – this will help you adapt to market disruptions flexibly and develop new products and services quickly, allowing you to meet customer demands more easily. This level of flexibility and agility, due to having these greater-depth insights, allows for quick decision-making. It can significantly unlock value and opportunities across the entire supply chain.

Optimise efficiency – introducing lean manufacturing processes that incorporate automated systems can optimise efficiency and increase output, which in turn boosts sales and revenue.

Reduce machine downtime – with the right automation, you can operate 24/7, providing operational efficiency and higher levels of productivity while reducing costs and lowering the chances of incidents in the workplace.

Gain vital insights – Connecting machinery and devices to gather data and provide analysis in real-time is a significant benefit to businesses as they seek to capitalise on future opportunities and improve production lines.

Meet market demand and deadlines – automation is incredibly adaptable, allowing for quick changes in processes and production to cost-effectively meet varying workloads at different periods throughout the year.

Maintain quality standards – Automation improves safety, precision, and quality by considerably reducing the risk of human error. This means you also mitigate the risk of defects and the need for reworks.

Manage the current staffing crisis – machines and automation can carry out repetitive routine tasks, freeing up staff and allowing you to upskill your workforce in other areas.

Save money and time – improving efficiency can considerably reduce costs. In addition, automation can reduce expensive repairs and machinery issues in the future.

Core Areas of Automation That Drive Long-Term Success

There are three key areas to automation:

Design and Build – special purpose-built, bespoke automated equipment that allows you to bring your new product to market.

Machine Integration – Enhancing your existing machinery to improve functionality and increase manufacturing capability.

Machine Refurbishment – improve machinery uptime by implementing automation upgrades and solutions to improve specific manufacturing components.

Futureproofing your business with automation

Introducing and implementing automation into manufacturing no longer feels like a choice if you want to enhance business resilience and remain agile.

However, it’s vital that you introduce the right automation systems for your business.

Understanding these emerging technologies, knowing your production lines and product pipeline, and seeking out solutions that can enhance your processes and improve efficiency are key.

At Innomech, we work collaboratively, looking at automation solutions that allow you to increase capacity, reduce costs, develop capability, and mitigate risk.

If you’re ready to futureproof manufacturing with automation, we’re here to help.